Filter

74 %

rates

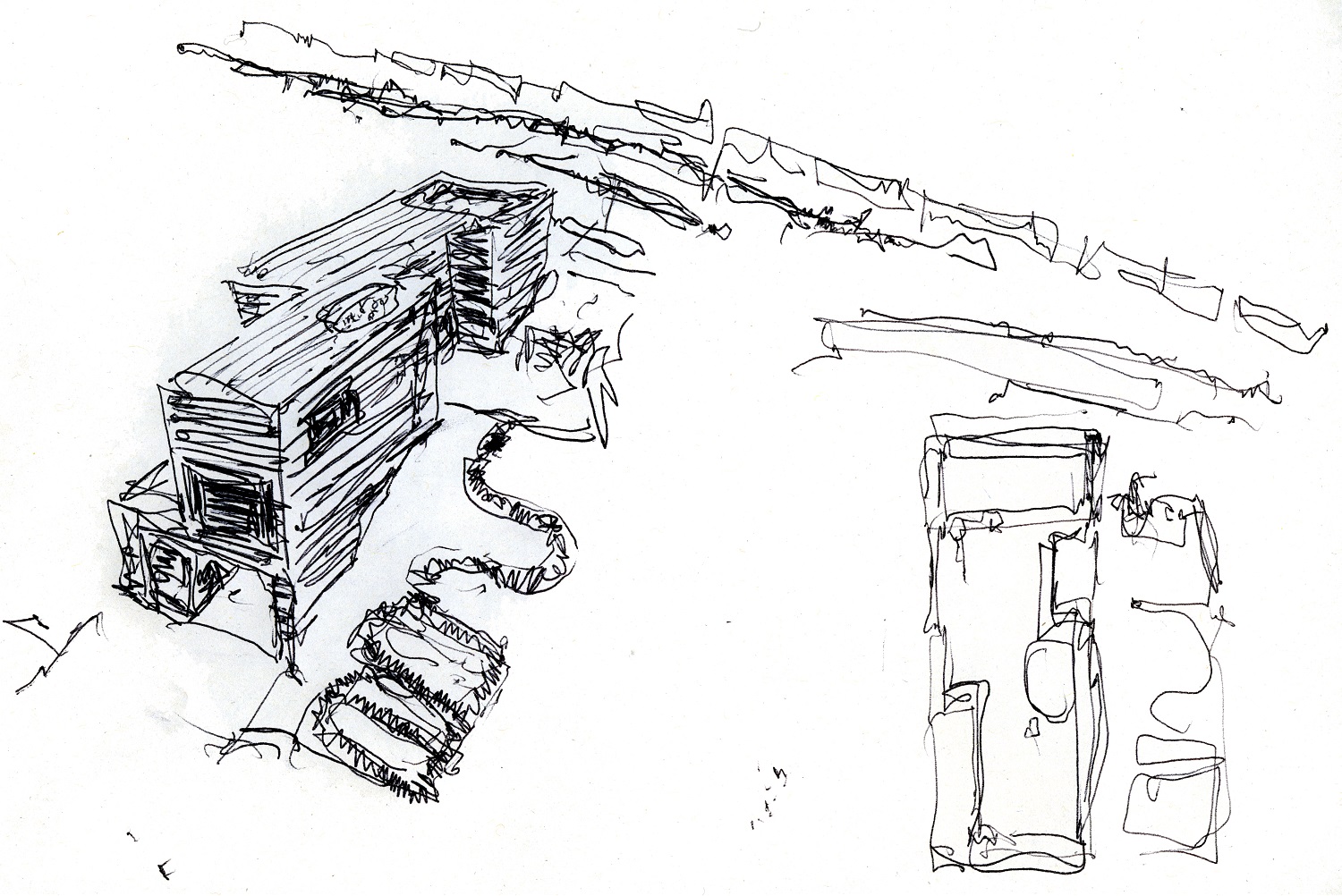

Martin Rauch's three-storey house is justifiably famous for the architect's rigorous work with natural materials from beginning to end. For that reason, it’s inspiring to look back once more at some of Rauch's reflections and to examine the technical approaches and parameters used in its construction.

After many years of building with earth and collaborating with many designers and architects, I realised that the biggest barrier to building with earth is insufficient confidence in this material. Confidence doesn't come from study. It can only be gained through direct practical experience during specific construction processes. This house made of rammed earth is the result of many years of experience and innovation. It is created from the belief that structural stability and high-quality surfaces can both be achieved through aesthetic design and craftsmanship of entirely natural materials.

The exterior

The 45 cm-thick rammed earth walls are composed entirely of material excavated on site. A mixture of B150 concrete (low cement content) with trass (a naturally formed pozzolan) was poured between the continuous footings directly onto the rocky substrate. Steel reinforcement was intentionally omitted.

Due to the increased costs for formwork, reed mats were chosen for the insulation. Due to their high silicon content, reeds are one of the few renewable materials that can be used without preservatives. Reed mats are available in large dimensions (200 x 100 x 5 cm) and serve as an effective natural insulation material.

The clay plaster is about 3 cm thick and was made from a mixture of local sand and earth from the construction site. It was applied to the wall using a clay plaster pump and was fully reinforced with linen fabric. After drying completely, the surface was plastered in several steps with 3-4 mm thick clay finishing plaster and smoothed with water. This created a silky, matte ivory surface without grain. All clay plaster surfaces were intentionally left untreated.

Transitional components

The relationship between the wall surfaces and the windows is subject to the static qualities of the materials used. In traditional rammed earth structures, windows are typically tall and narrow, but the architectural design of Haus Rauch called for large windows. It was a challenge to create these large window openings, both in terms of construction and static stability.

All the doors and windows are mechanically connected to the rammed earth walls; no glues or foams were used during construction. The joints were retouched and sealed with moist clay. Larger joints between windows and the earth walls were filled flax-reinforced clay. Thanks to the excellent properties of clay, which can extract moisture from wood, these wooden components can be tightly joined.

The interior

Wooden materials were used for the sliding elements. The kitchen and bathroom furnishings were primed with a thin layer of a clay and casein mixture. This mixture is produced similarly to a white clay finishing plaster and is stabilised with the milk protein casein; together with lime, this creates a durable and very strong natural adhesive.

Like the walls, the floors were created using sieved excavated material, which was spread level and rammed. After ramming, the surface was sprayed with earth and then machine-sanded. Clay fills all the joints and crevices and smooths out uneven surfaces. Stones are visible and noticeable. The colour of rammed earth corresponds to the excavated material available for the construction.

The staircase was built in three stages, with each step constructed individually. A piece of round glass was inserted into each step in line with its surface; these support the vertical flow of light in the stairwell. The railing is a 1 cm thick free-standing, self-supporting sculptural structure. It was a challenge to come up with an aesthetically pleasing shape that would be achievable in a narrow staircase.

Acknowledgement of changes and surface ageing is part of the design and construction strategy. Clay is a crumbly, sedimentary rock, subject to erosion and disturbance. Erosion due to water, frost, wind and tectonic shifts is part of what makes our planet sustainable. Erosion and sedimentation are usually perceived as negative. We try to prevent erosion with protective structures, to direct it into prepared channels. Still, erosion is strong; it can't be prevented, only postponed. All surfaces are ultimately subject to erosion, so surface materials have an impact on both design and environmental compatibility. It’s exciting to acknowledge erosion and to design in harmony with it.

Credits

Architects: Roger Boltshauser, Martin Rauch

Collaborators: Ariane Wilson, Andreas Skambas

Project Manager: Thomas Kamm

Chief Engineer: Josef Tomaselli

Earth Construction: Martin Rauch and team

Joinery: Manfred Bischof

Ceramic Art: Marta Rauch-Debevec, Sebastian Rauch

Design and Construction: 2005–2008

Photos: Beat Bühler

.jpg)